Servo Motor Repair

Servo Motor Repair Services

Servo motors are immensely useful tools that pack a powerful punch for their size. They are similar to AC/DC motors, except they have an additional positioning device. The attached positioning device offers useful feedback for providing extra control in a closed system loop. Even though they are small, these motors give you tremendous power and efficiency.

Servo motors are becoming more and more common in today’s industries where precision and control of shaft position, rotation, torque and speed are needed. Servo motors can be found in just about every industry on equipment such as machine tools, robotics and anywhere there is an automated process, so having a trusted repair source for servo motors is key to avoiding costly downtime.

If your servo motor breaks down, you’ll need to know how to test for different issues and navigate the repair process. In the guide below, we’ll outline how servo motor repair services work, discuss some common servo motor problems and guide you through troubleshooting a malfunctioning motor before deciding on professional repairs.

Our Commercial Servo Motor Repair Process

Global Electronic Services’ certified technicians follow a strict, step-by-step process, which helps us deliver quality servo motor repairs. The process looks like this:

- – The repair is visually inspected for obvious failures such as burn marks, corrosion, fractures and poor connections.

- – The feedback cover is removed, and the device is closely examined. Electrical tests are performed to determine if the feedback can be safely powered. At this time the feedback is also disconnected so the motors windings can be checked without damaging it.

- – Motor windings are tested using an AWA analyzer. This device performs megger, high potential, resistance balance and surge testing on the motor.

- – In the case of servo motors utilizing magnets, KE or voltage constant tests are performed.

- – Machine work, including keyway, shaft repair and bearing journal work, is performed if needed.

- New bearings and sealing components are installed on every repair.

- – The feedback is tested on the Mitchell electronic system, whether it be resolver, encoder or tachometer.

- – If faulty, the feedback device is either repaired or replaced.

Our commitment to providing quality servo motor repair services with the steps above helps ensure your equipment will continue to work when you start using it again. It also means your company will get its equipment back quickly — we stock thousands of parts to avoid ordering delays, and we can provide free rush turnarounds in 24 to 48 hours for emergencies.

Because we use the latest technology in our testing, we can uncover even the smallest, undetectable flaws. And because we test a variety of failure-prone components as well as the ones currently giving you trouble, your equipment will come back with a full 18-month in-service warranty.

Our commitment to quality repairs begins even before the repairs get started. We offer free estimates so you know what costs you’ll be dealing with before the repairs happen. Have you ever been to the doctor or the mechanic and been quoted one price, only to find yourself holding a bill that was many times higher? We do better. When we repair a servo motor, we’ll let you know how much repairs are going to cost so you can plan for them — they’re typically very reasonable — or make other arrangements.

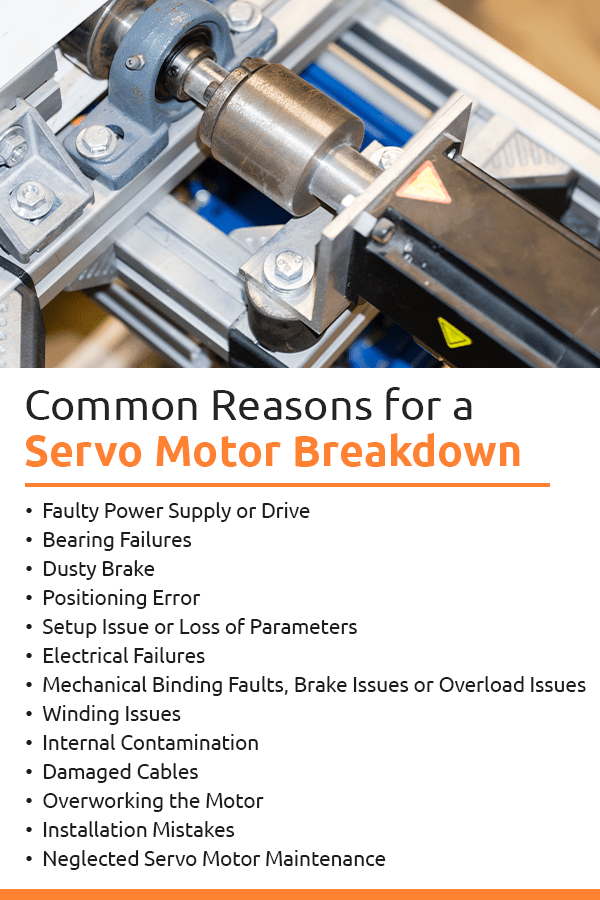

Common Reasons for a Servo Motor Breakdown

If your company uses a servo motor frequently, you may want to be familiar with typical reasons for motor breakdowns. Learning more about how your servo motor works and how it may malfunction can help you troubleshoot problems and know when to take your motor to the professionals for repairs. Here are a few common servo motor issues and how the right repairs can resolve them:

1. Faulty Power Supply or Drive

One possibility is that the servo motor could have an inadequate power supply or a bad drive. In this case, the motor itself is fine, but failures of the external systems cause it to malfunction. A faulty drive or power supply can damage a servo motor by creating a voltage spike or irregularity in the power flowing to the motor. Often, the winding will need to be rewound.

2. Bearing Failures

Often, what ails a servo motor is a faulty bearing. A worn or unlubricated bearing can cause a shrill screeching noise or whine, so if your motor is exhibiting that symptom, the bearing could be the cause. Sometimes you can change settings and parameters to compensate for this issue, but if that doesn’t work, you’ll probably need to get your servo motor a bearing replacement. Be sure to do so right away — over time, a faulty bearing can lead to total motor failure.

3. Dusty Brake

Dusty brakes can also cause a high-pitched squeal from your servo motor. If your servo motor has a brake, dust from the brake pads may have infiltrated the brake itself. Then the dust can move to the bearings, soak up the oil, and lead to friction and screeching. Even though servo motor bearings usually have shielding, dust can often find a way to creep in and compromise them.

4. Positioning Error

A positioning error can also cause problems for your servo motor. If this happens, the motor will stand still and make a buzzing or chattering noise, and the output shaft will waver slightly, even though it is at rest.

5. Setup Issue or Loss of Parameters

Setup issues and parameter losses in the drive can cause positioning errors that can affect performance or cause outright damage to the servo motor. You can check to see whether these setup issues are the cause of the malfunction by running through the setup procedures for the servo motor and drive. If not, the servo motor may require repair.

6. Electrical Failures

Capacitors, resistors, diodes, encoders, resolvers and other electrical components all wear out over time. As your electrical equipment degrades, it will eventually start to compromise your motor’s performance and require repairs.

7. Mechanical Binding Faults, Brake Issues or Overload Issues

Issues with your servo motor’s mechanical binding or brake can also cause the motor to run hot. Overload issues within the circuitry can do the same. If your motor is running hot and you suspect these causes, get your motor repaired right away to avoid further damage.

8. Winding Issues

If something goes wrong with a servo motor’s winding, the motor may begin to run hot, and running hot can lead to damage. Contamination in the winding could be causing the trouble, or an internal short may have occurred. Either way, you’ll need to have the problem repaired so you can get your servo motor running cool again.

9. Internal Contamination

If contaminants such as dirt, oil, cutting fluid and coolant get into the motor’s internal workings, they can cause damage to the components — particularly the bearings, windings, encoder and electrical components of the motor. The contaminants gum up the parts and keep them from functioning as they should.

You can try to prevent contamination by using fluids carefully and keeping the machine clean, but if dirt or fluids begin to compromise the integrity of essential components, repairs will become necessary.

10. Damaged Cables

If a cable has become damaged, your servo motor may break down. Damaged cables are relatively common, and they can also cause voltage spikes that damage the motor.

11. Overworking the Motor

Your servo motor is likely to become damaged if it experiences overload or runs too long. You can help prevent this issue by giving your motor enough downtime and ensuring appropriately sized loads.

12. Installation Mistakes

It’s also possible that a mistake occurred in the initial installation of your servo motor and is now causing the motor to malfunction. Mistakes do happen, and an improperly installed servo motor can have a host of issues. It may be coupled to a worn-out ball screw or gearbox. It may have belts that are too tight. Or it may be slightly out of position — and even minor errors in position can diminish a servo motor’s performance.

13. Neglected Industrial Servo Motor Maintenance

Neglecting to perform the required maintenance on your servo motor can cause some of the problems outlined above. Bearings may wear out, or oil and other fluids can build up over time and lead to breakdowns. Scheduling basic industrial servo motor maintenance once in a while can help avoid the need for some costly repairs.

Servo Motor Maintenance & Troubleshooting

Some servo motor problems occur for common, easy-to-fix reasons. Servo motors also typically trigger an alarm to signal something isn’t right, so you’ll often have a clear indication of trouble even if you don’t know what the problem is. If you see an alarm or your servo motor doesn’t seem to be performing the way it should, you can troubleshoot to uncover the issue.

Keep in mind that servo motors are complex machines. Your team will need to have expertise with electromechanics, actuators, and voltmeter and ohmmeter use. If you’re unsure how to proceed, it’s best to let professionals handle the troubleshooting quickly, thoroughly and safely.

Below is a short guide to troubleshooting problems with your servo motor:

1. Check for and Prevent Overheating

Overheating is a common reason for failure in servo motors, especially when they have been running for a while. Overheating is particularly common in the summer, but it can occur in the winter too. It is particularly common in older machines where the components are beginning to wear down.

Most servo motors have failsafes that shut them down automatically when they reach a dangerously high temperature. But overheating can still cause damage and necessitate repairs.

Your company can take a few different steps to prevent overheating:

- Regulate the temperature: Climate control in your facility is essential for ensuring your machines’ high performance and longevity.

- Be careful with fans and open cabinets: It can sometimes be tempting to direct fans at your servo motor or open the cabinet when the motor is overheating. But both of these actions can lead to further damage. Fans can blow dust and debris into the motor and jam the components. And fans and open cabinets can strain the motor by making it work harder than it would otherwise.

- Replace parts: If your servo motor is old and its parts are wearing out, consider having those parts replaced. If all the motor’s components are intact and functional, overheating will become much less likely.

- Turn the motor off: If your motor is overheating, remember to turn it off right away. A little downtime gives the motor a chance to cool down before any permanent damage occurs. However, if you’re turning off your servo motor so frequently that your facility’s productivity begins to drop, it may be time to have the motor replaced.

2. Check the Drive

If your servo motor doesn’t run at all, the problem could also lie with the drive. To check the drive, you can turn your servo motor off and then turn on the machine or main breaker. The LED screen or readout display will likely light up first. Pay attention to when an alarm comes on to indicate a problem with the motor. If the alarm comes on before any other parts have powered on, the issue is likely with the drive.

3. Run a Self-Test

To rule out the possibility of drive problems, you can also run a self-test, which causes the motor to operate at minimal efficiency. If you do that and everything seems to be working fine, the drive is probably not the issue. If the motor still won’t run, the drive will need repairs.

4. Check DAC Output

If your servo motor refuses to run entirely, you can also check the digital-analog-converter (DAC) output. There may be a problem with the controller, and you can find out by checking the DAC parameter. If it’s zero or almost zero, you’ve uncovered the problem. You may need to replace the controller in this case.

5. Check Grounding and Power

If your servo motor is making a strange humming noise, there’s likely an issue with the electrical components or faulty wiring. After turning the motor off, check that it’s grounded correctly and is receiving enough power.

6. Check for Torque Issues

Different servo motors are designed to produce different amounts of torque. If your servo motor provides less torque than you need, it won’t be able to do the work you require.

Even if your motor is capable of producing sufficient torque, issues like its amplifier rating, its workload limits, low voltage, system voltage drops, faulty capacitors and bad connections can lead to inadequate production. Check all these aspects of your servo motor’s function to see if you can discover and remedy the problem.

7. Inspect the Wires, Bearings and Cooling System

If your servo motor is smoking or giving off an acrid smell, that’s a sure sign something is wrong and your system is overheating. To figure out what’s happening, check the wiring, cooling system and bearings. The cooling system may have become impeded because of debris or dust particles. The bearings may be worn down, have too much lubricant or be overheating. Or the wires may be burning because they have come into contact with each other or are improperly grounded. It’s also possible that the coolant has seeped into the electrical box.

8. Probe Into Causes of High-Speed Malfunctions

In some cases, your servo motor may start running fine but have problems when it reaches high speeds. If your servo motor emits a loud growl at high-speed operation, there’s likely a problem with the bearings. Otherwise, you can check for a few different potential causes:

- – Blown or worn-out fuses

- – Extreme overheating

- – Inadequate overload protection

- – Faulty wiring

- – Voltage drops

- – RPM meter inaccuracies

- – Faulty capacitors

9. Inspect for Damaged Cables

Because damaged cables can cause damaging voltage spikes, you should always check the cables when you suspect something’s not right with your servo motor. Cables are much easier to replace than motor components, so catching this issue early could help you save time and minimize your repair costs.

10. Run Setup Procedures

If your servo motor is chattering, it’s a good idea to rerun setup procedures. It’s especially important to do this if your equipment has autotune capabilities. Your drive may have gotten reset without your knowledge, and if so, rerunning setup procedures should help get your motor operating smoothly again.

Industrial Servo Motor Maintenance Services

Global Electronic Services is a qualified one-source solution. We can perform maintenance and repairs on all encoders, tachometers and resolvers for all servo motor repairs. You get everything you need in a single industrial servo motor repair service.

Part of our rigorous review includes feedback testing and repair. This maintenance is necessary because it ensures your servo motor and drive are at top performance. Feedback devices give us a way to deliver information to the control for speed, rotation direction, position accuracy, deceleration, acceleration rates and relative position of the rotor to the stator.

Here are just a few of the feedback tests and devices included in our industrial servo motor maintenance and repair offerings:

- – Checking the pulse stream of all waveforms with an oscilloscope

- – Checking the relationship of the A, A*, B and B* signals with an oscilloscope

- – Checking the Z and Z* signals with an oscilloscope

- – Line level checking all lines to verify that none are missing

- – Line counting with a digital pulse counter

- – Running at continual count at operating speed check

- – Measuring the offset from signal A to signal B

- – Measuring the time “on” versus the time “off” of the pulses

Contact Global Electronic Services for Quality Servo Motor Repairs

To see the benefits of quality servo motor repairs for your industrial equipment, partner with Global Electronic Services. When you choose Global Electronic Services to repair servo motors for your company, you’ll work with friendly, knowledgeable, factory-trained and certified technicians and receive quick, correct and durable repairs.

For more information, request a quote online today.