Power Supply Repair Service

Quick Links: Why Global Electronic Services | Power Supply Repair Process | Types of Power Supply | Contact Us Today

Any business that uses an industrial power supply needs a reliable repair service. When a power supply goes out, companies are faced with unexpected downtime that can derail projects and drive down revenue. Global Electronic Services is prepared to provide efficient repair services for any industrial power supply, so your business can minimize the impact on operations when equipment fails.

Why Choose Us for Industrial Power Supply Repair?

Your business has hundreds of options when it comes to industrial power repair. So, what makes Global Electronic Services the right choice, and how do we provide service that outperforms the rest? Here are seven key advantages to consider:

1. In-House Service

Many electronics companies take shortcuts and outsource a portion of their work to other businesses. They do this as a way to cut costs, and the practice comes with serious drawbacks for the end customer. Poor communication and lack of transparency make it hard to know who’s really handling your company’s repair needs, and it’s often difficult to get up-to-date information on how the repair is going.

Global Electronic Services does all repairs in-house, so your company can rest assured that all power supply repair is performed by our experienced repair technicians. It also means we have thousands of common components ready to go and don’t have to wait for various parts to come in like many other companies do. We even stock obsolete components, allowing us to perform repairs on power supplies that other companies simply don’t have the parts to service.

2. In-Service Warranty

When your company has a power supply repaired, you expect the repair to be more than a band-aid fix. Many repair services will do a rush job to patch up a power supply but do not offer any guarantee that the work they’ve done will hold up. This means that many companies end up sending the same unit back in for repair, or end up prematurely replacing a unit that could have many years of life left if a quality repair is performed.

To increase customer confidence in the quality of our service, we offer an 18-month in-service warranty on our repairs. That means, even if your company keeps the power supply as a backup, it’s still covered for 18 months, starting at the time it is put in service.

3. Quick Turnaround

While industrial power supply repair can be an in-depth and complicated process, that’s no reason to make your company wait longer for equipment to be repaired. Thanks to our streamlined process and skilled repair technicians, Global Electronic Services has a standard turnaround time of one to five days.

When you speak to a representative or request a quote with the details of your power supply problem, we can provide an estimate on how long the repair will take, so your business can plan accordingly.

4. Rush Service

Many repair services simply don’t have the capacity to provide rush services. Global Electronic Services is prepared to take on emergency repair cases and have your company’s power supply repaired and shipped back in 24 to 48 hours whenever the need is urgent.

With one repair facility on each coast, Global Electronic Services can have your newly repaired power supply back to your business faster. The best part of the rush service is that we offer it at no charge. We understand what it’s like to have a power supply emergency, and don’t take advantage of your company’s situation.

5. Price Guarantee

When a power supply fails, your company needs to find a balance between adhering to the budget and finding a quality repair provider. Global Electronic Services takes the headache out of searching with our price guarantee. We will beat any quote you bring us by 10%, giving you peace of mind that your company is getting the best value in the industry.

6. Full Load Testing

Some companies use their warranties as a way to skip over the all-important process of testing their repairs. When this happens, companies end up sending in the same equipment for repair multiple times because it isn’t vigorously tested. While the repairs may be free, the frustration and downtime caused often aren’t worth it.

Global Electronic Services pairs our industry-leading warranty with full load testing during the repair process, helping minimize the chances you will need to use the warranty after the repair is complete.

7. Process Tracking

Not knowing what’s going on during the industrial power repair process can cause severe frustration and make it hard to plan around your company’s power supply repair. That’s why we offer process tracking through our customer portal. Simply log in and track where each order is in the repair process. You can also view your order history, pay for orders and approve quotes through the convenient portal.

Industrial Power Supply Repair Process

Global Electronic Services has a five-stage repair process designed to provide expert repair with streamlined efficiency. When your company is having a power issue and sends in a power supply for repair, it will go through the following process:

1. Receipt

Upon receiving a request, the repair is immediately logged in our system with its own unique barcode for tracking. A technician completes an initial evaluation of the repair and generates a list of the parts needed to complete the repair. Using this parts list and evaluation, we create a quote for your company within 24 hours and submit it for approval via a phone call and confirming email.

2. Evaluation

Once your company approves the quote, we assign a technician to the power supply unit. The technician disassembles the unit and begins troubleshooting the equipment — this involves finding electronic signatures and determining their functionality as well as their performance.

3. Repair and Testing

Using the information learned in the previous step, the technician performs true load testing and runs simulations to find out the conditions under which the unit fails. This provides the necessary information to complete the repair.

After the technician completes the repair, further testing under load conditions ensures the unit is functioning optimally.

4. Final Preparation

Some companies perform repairs but do not take the extra steps to ensure the unit is fully ready to go once the customer receives it. This can result in your company receiving a unit that is functional but needs additional cleaning before it can be put back into service.

At Global Electronic Service, we go the extra mile. Once the repair is complete and tested, the unit goes to the cleaning station. Technicians use cleaners formulated for electronics, including degreasers and oil tracers. Some repairs require time in a drying room to ensure moisture evaporates completely. This cleaning step ensures that the unit is ready for installation the moment your company receives it.

5. Quality Assurance and Shipping

Our experienced quality assurance team does one more round of checks to make sure the power supply unit is fully functional and ready to go back into service. Once this is confirmed, the repair is prepped for shipping.

We understand the importance of proper packaging and take multiple measures to ensure safe shipping. We determine packaging needs based on the size, shape and weight of the repaired item. When necessary to protect the repair, we provide custom packaging for shipment.

After we ship the power supply back to your company, we create a detailed invoice which is available for viewing in the Secure Customer Portal.

Types of Power Supply

A power supply unit is a device that converts electrical power to the correct frequency, current and voltage of a particular load circuit. The power source can be either AC (from electricity) or DC (from batteries or solar devices). While power supplies typically convert one type of electric power to another, they can also convert other forms of energy, like solar or mechanical, to electrical energy. Let’s take a look at some of the most common types of power supply:

1. Variable AC Power Supply

A variable power supply includes a way for users to change the output voltage, and, in some cases, the current. Variable AC power supplies use transformers or autotransformers to change the AC-to-AC voltage and current while leaving the power source frequency the same.

2. Frequency Changers

When the frequency of AC power needs to be altered, a frequency changer is the appropriate type of power supply. These supplies may use devices such as a motor-generator set or a rectifier-inverter set. In the latter case, the rectifier converts AC power to DC power, and the inverter then changes the DC power back into AC with a different frequency.

3. Isolation Transformers

Isolation transformers transfer electrical power from an AC source to a device or piece of equipment, while keeping the powered device isolated from the power source. They are used when impedance matching is necessary and allow for the most efficient transfer of power between stages.

4. Unregulated Linear Power Supply

Unregulated linear power supplies provide simple AC-to-DC conversion. Their design includes:

- A step-down transformer

- Rectifier

- Filter capacitor

- Bleeding resistor

The first step in this power supply is the transformer changing line voltage to the necessary AC voltage level. A half or full-wave rectifier using diodes then converts the stepped-down AC voltage to DC voltage. Filter capacitors smooth out the resulting DC. There may or may not be a bleeding resistor connected to the capacitor as an extra layer of protection.

The benefits of unregulated linear power supplies include durability and simplicity. The downsides include variation in output voltage and a design that can only output a single voltage and current.

5. Linear Regulated Power Supply

Linear regulated power supplies convert AC power to DC. The conversion process is the same as with an unregulated power supply, but with the addition of a transistor circuit instead of a bleeding resistor. This regulator circuit enables the supply to convert main AC voltage into a stable DC voltage, which is ideal for devices that need a steady and consistent supply.

These power supplies are more expensive, larger and less energy efficient than unregulated linear supplies. They tend to lose significant amounts of energy due to the dissipation of power, so they may need to be used alongside a heat sink with an integrated circuit (IC) regulator.

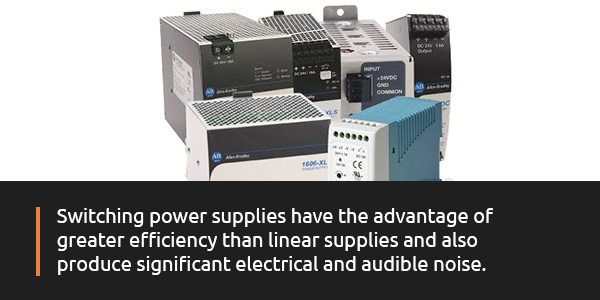

6. Switching Regulated Power Supply

Switching regulated power supplies, or switch mode power supplies (SMPS), are available in AC-to-DC or DC-to-DC configurations. They use a complicated, high-frequency switching method with pulse width modulation and feedback to regulate output. These supplies turn the switching transistor on and off to create a chopped DC voltage. That voltage goes through a rectifier, producing the final desired DC output, which is filtered before the supply passes it to the load.

Switching power supplies have the advantage of greater efficiency than linear supplies and also produce significant electrical and audible noise.

7. Ripple Regulated Power Supply

This type of power supply is an update to unregulated linear supplies. It is based on an unregulated power supply and has a transistor circuit in the saturation region, which works to maintain the desired voltage by transferring DC power to a capacitor. Ripple regulated supplies are used in applications where ripple causes problems, and are very efficient compared to unregulated supplies.

8. Adjustable Regulated Power Supplies

An adjustable, or regulated, power supply allows the user to adjust the output voltage continuously. This is valuable in testing projects to make sure parts placement matches circuits. These supplies are based on linear regulated supplies but modified with a variable resistor. The resistor allows the supply to provide voltages from zero all the way to the maximum allowed by the supply.

9. Battery and Solar Power Supplies

Solar panels and batteries provide a supply of DC power, but that power must be filtered, so no pulsating ripples remain. After filtration, voltage regulator ICs can regulate the supply to the required voltage level. Should a user need to step up the voltage, they can use transistors to amplify the supply voltage.

10. DC-To-DC Converters

When a user needs to step DC voltage up or down, a DC-to-DC converter is the appropriate power supply. They come in three possible types:

- Electrochemical

- Electromechanical

- Semiconductor

Semiconductor converters are the most common, and also come in a variety of types including:

- Push-pull

- Buck

- Boost

- Buck-boost

DC-to-DC converters allow users to create different levels of DC using one supply, instead of having to use multiple AC-to-DC supplies to power a device.

11. DC-To-AC Power Supplies

This type of power supply is also known as a power inverter. Because DC power is often too low in voltage to power AC devices, DC-to-AC power supplies are typically used as a backup in case of power failure. A power supply of this type will take power stored in a battery or cell and convert it to AC voltage appropriate to power the device in question.

Contact Us for Your Industrial Power Supply Issues Today

When your business needs a power supply repaired, trust Global Electronic Services. With extensive experience in the electronics industry, we offer unparalleled customer service and highly skilled repair work. Global Electronic Services is proud to maintain a customer return rate of more than 98%, and we invite your company to find out why.

To find out more about our services or begin the repair process, call 977-249-1701 or request a quote online.