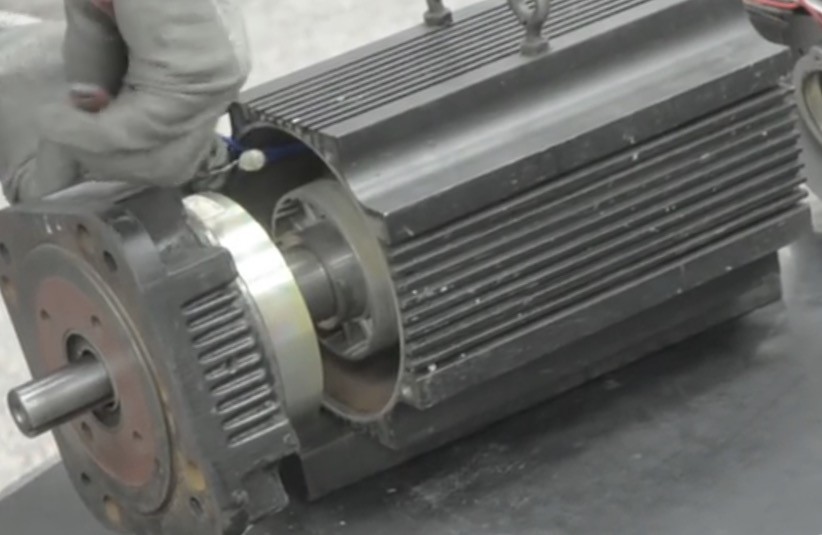

Servo Motor Repair – Step-By-Step Process

Servo motor repair is claimed by many but mastered by few! There are many steps involved in repairing servo motors; the trickiest step is in the feedback repair and realignment. This small step is the key to accurately repairing the servo motor, without a perfect alignment the rest of the servo motor repair is irrelevant. To perform the perfect alignment a repair company must use a very expensive alignment system, it is due to this cost and the lack of an ability to repair the electronics of the feedback device that many repair companies do not repair servo motors. We would like to invite you to watch our servo motor repair process in the video below. This is how we can accurately repair, realign and fully load test your servo motors for a perfect repair every time!

Servo Motor Repair Process:

Initial Evaluation

During an evaluation a visual inspection is performed to check parts like the shaft, keyway, endbells, terminals and connectors. After the inspection a surge comparison test, or short test is performed to verify if the stator will need to be rewound. Next, an insulation resistance test, often called a megger test, is performed in each phase to make sure the insulation in not broken down. The next test in the evaluation is the phase balance test where an RMS meter is used to make sure the windings are balanced in between phases; this is also where the brake is verified if the servo motor has one. The KE test follows to test the conditions of the magnets inside the servo motor. The final stage in the evaluation is using our Mitchell Electronics System, using the TI-5000 a test of the feedback device is performed on the servo motor.

Disassembly

First, the backplate is removed, followed by the encoder and encoder housing while carefully disconnecting the wiring. Then the endbells are removed and the rotor is pulled from the stator; here the rotor and shaft will be visually inspected. Next the bearings and bearing housing is removed as well as the brake.

Cleaning

An alkaline washer is used as it is better for your motor than hand cleaning or pressure washing. All of our motor parts are washed this way.

Bearing Change

It is important to change every bearing every time as they are often the cause of failure in a motor. We only use high quality bearings that meet or exceed all manufacturers specifications. Once the bearings are changed the motor is reassembled.

Final Testing

To ensure the motor is fully repaired, a retest at the Mitchell Electronics TI-5000 is performed as well as a count test. Next a memory test is performed to ensure the realignment of the feedback device. After the repair is fully tested and verified the motor is painted and is ready to send back to you, ready to use!

Please watch the video below to see step-by-step, in full detail, how a servo motor is fully repaired, realigned and tested!

Free rush service, 1-5 day standard turnaround, free evaluation, 10% price guarantee, an 18 month in-service warranty and 24/7 support are all standard benefits at Global Electronic Services! Be sure to visit us online at gesrepair.com or call us at 1-877-249-1701 to learn more about our services. We’re proud to offer Surplus, Complete Repair and Maintenance on all types of Industrial Electronics, Servo Motors, AC and DC Motors, Hydraulics and Pneumatics. Please subscribe to our YouTube page and Like Us on Facebook! Thank you!